Kingrig Group Ltd is a leading provider of oilfield equipment, services and solutions. The below is our capacities for mud pump parts:

We provide a full range of replacement parts for most mud pumps: from the extension rod to the fluid end. All of our parts are 100% interchangeable with the OEM. Every part is manufactured under quality standard and strict inspection prior to the delivery.

Our mission is to supply quality spare parts and best service to international drilling contractors through our distributors all over the world.

We offer a full line of mud pump parts for most popular mud pumps in the world, including but not limited to below:

BRAND | TYPE |

Ellis Williams | HT-400-D, W-400-LP, 9-W-1000, 14-W-400, 15-W-600, GA-550L 21.50”, 14W400, 15W600, W446, EW-440, EW-446 |

Emsco | F-350, F-550, F-650, F-750, F-800, F-1000, F-1300, F-1600, FB-1300, FB- 1600, FA-750, FA-1300 TYPE II, FA-1600 TYPE II, FC-200, CA-16, B-A-14, D-12, D-14, D-16, D-125, D-175, D-225, D-300, D-375, D- 500, D-550, DA- 500, DA-700, DB-550, DB-700, D-700, DC-700, D-1000A LB-200, LB-300, LB-400, LB-500, LB-650 |

Gardner Denver | PZ-7, PZ-8, PZ-9(PV-9), PZ-10, PZ-11, PY-7, PZ-GA, PZ-L, PZ-K, PE-5, PA-5, PA-8C-Y, PA-8K, PAH-BFB, PAH-BFC, 7500PSI M, PJ-8A, PJ-8, O559450, KG-KXG, KG-KXF, FZ-FXZ, FY-FXD, FY-FXX, FXZ-FXZ, FXN- DMA, FXO-FXO, FQ-FXQ, FO-FXO, FK-FXK, FG-FXG, FF-FXP, FF-FXF, FD- FXX, FD-FXD A-G, GR-G XR, GR-GXP, GP-GXR, GP-GXP, GQ-GXQ, GQ- GXN, EF-FXD, TEE-5, KT LEE-5P8, P29, SW-400, SW-500 |

Gaso | FIG.3673, FIG.2651 |

GAPCO | GA 550, GA 750 |

Ideco | T-500, T-800, T-1000, T-1300, T-1600, NEW T-1300, MM-300-A, MM-450, MM-500, MM-550-F, MM-600-F, MM-700-F, L26”XODTL-120, TL-200, TL- 300, TL-400, TL-500 |

National | 7-P-50, 8-P-80, 9-P-100, 10-P-130, 12-P-160, 14-P-220, N-1100, N-l300, N- 1600, K-380, K-500(CAST), K-700, JWS-165-L, JWS-400, H-700, H-850-A, G-1000, G-1000-C, E-700, C-150, C-150-B, C-250, C-350, K-500A, P-200, P-300, P-400, P-500, P-650, P-750, K-700A, N-24, N-35, N-47, N-69, N-815, N-1324 |

Oilwell | 350-PT, 850-PT, 1100-PT, 1400-PT, 1700-PT, A-350-PT, A-560-PT, A-600- PT, A-850-PT, A-1100-PT, A-1400-PT, A-1700-PT, 14-P-HD, 20-P, 212-P, 214-P, OWS 214-P, 218-P, 220-P, 712-P PC-100, PC-150, PC-225, PC-300, PC-425 |

OPI | GIST 500, 750, 700-DL, 700-HDL, 1000-DL, 1000-HDL, Omega D-750 |

Skytop Brewster | B-500-F, B-550-F, B-750F, B-1000-F, B-1000-T, B-1100-T, B-1300-T, B- 1600-T, 1338G, L26”xOD |

Wheatley | WH-4000 A.B |

Wilson | W-250-C, 600 |

Others | UU-162, TD-182, Piston Testing Sleeve, P-637, OIME 500, FMC, 3-1/2x5 |

Wieth | TPK-1000, TPK-1300, TPK-1600, TPK-2000, TPK-2200 |

Drillmec | MaHB.1000 7TS-500, 7T-450-B-M, 8T-300M, 8T-600, 12T-1600 |

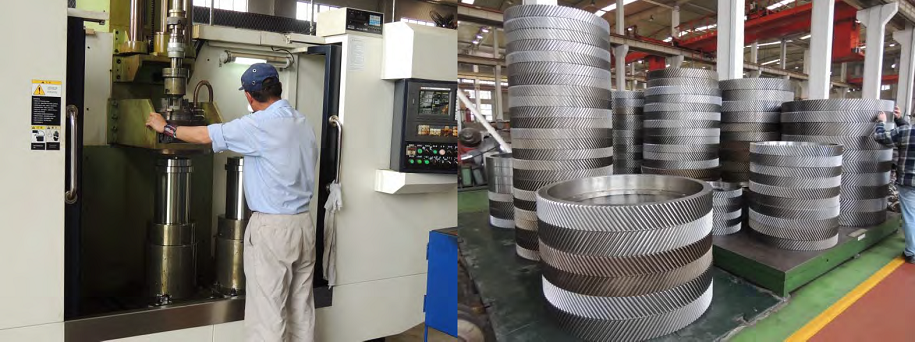

Inspection & Production & Testing facilities:

Inspection: We have full sets inspection equipment for chemical & physical composition inspection.

Heat-treatment: With advanced techniques, such like: Carburizing, Hardening, Tempering, Backfire, Carbonitriding, Vacuum hardening, This well guarantee the quality for heat-treated parts.

Forging: We have a full line forging facility to ensure we can manufacture quality forged parts ourselves. Our 1-ton, 5-ton and 16-ton hammer forging and die forging enable us to produce almost all forged work pieces of fluid end parts.

Machinery: The using of CNC machine to ensure the accuracy & machinery quality.

Final inspection: 100% final inspection to ensure the products are correct.